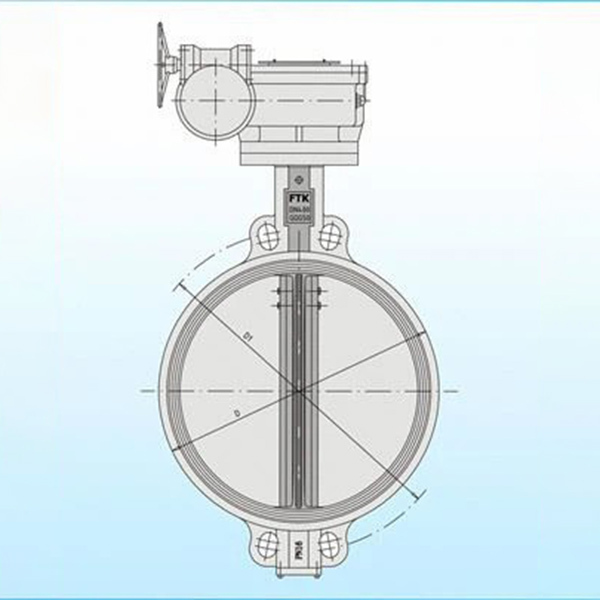

General Description:

Resilient seated butterfly valves are widely used in various industries for both On-off and regulating service. Compare with traditional globe & ball valve, butterfly valve is less weight and cost effective. Followed by the rapid development on various elastomer material, resilient seated butterfly valves are now used not only for water system but also for various chemical industry.

Design Standard:

Basic Design: API 609, BS5155, EN593

Face-Face Dimension: ASME B16.10, API609, EN 558-1 Series 13 & 20

End Connection: ASME B16.5, ASME B16.47, MSS SP44, DIN 1092-1

Test: API 598, EN12266

Marking: MSS-SP-25 / EN 99

Products Range:

Size: 2″ ~ 64″ (DN50 ~ DN1600)

Rating: 150 ~ 232Psi, PN10, PN16, PN25, PN40

Body Materials: Cast Iron, Ductile Iron, Cast steel, Stainless steel

Seat Material: EPDM,NBR,VTION, PTFE

End Connection: Wafer, Lug, Double Flange

Design Feature:

Concentric design

2-PC shaft low torque design

Bi-directional service

Self cleaning

Blow-out proof shaft

ISO 5211 top flange

Optional extended stem

Application:

Potable water supply

Power plants

Shipbuilding industry

Chemical and petrochemical

Paper mill