General Description:

Flowtek’ DBB plug valve can be manual or electrical operated, which is also called Twin Seal Plug Valve.

Design Standard:

Basic Design: API6D / API599 / BS5353 / GB/T22130

Face-Face / End-End dimension: API 6D, ASME B16.10, EN 558

Flange / BW Ends Dimension: ASME B16.5, EN 1092, ASME B16.25

NPT Ends: ASME B1. 20.1

Fire protection: API607

Test: API 6D, BS 6755, API 607, API 6FA

Products Range:

Size: 2″ ~ 24″

Rating: ANSI 150lb ~ 900lb

Body Materials: Carbon steel, Stainless steel, Alloy

Trim: WCB+Nitriding, CF8, CF8M, CF3, CF3M, 4A, 5A, INCONEL625

Seat: PTFE, R-PTFE, TFM1600, NYLON, PEEK, PPL

Operation: Lever, Gear, Motor, Pneumatic operator

Design Feature:

Full port or Reduce port

Fire safe design

Double block & bleed

Emergency sealant injection

Cavity pressure self relief

Blowout-proof stem

Anti-static

Application:

On shore Oil & Gas

Off shore Oil & Gas

Refinery

Chemical

Petrochemical

Power plant

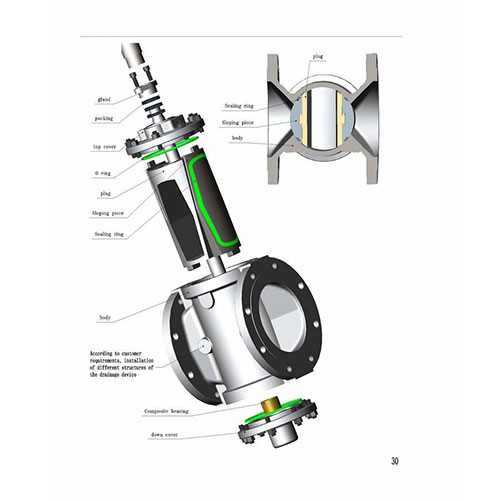

Structure features

1, the middle flange double seal structure rail plug valve is mostly used for aviation kerosene, natural gas, liquefied petroleum gas, product oil, etc., because aviation kerosene and other media has a strong permeability and flammable and explosive, in order to prevent leakage of the medium, in the middle flange using o-ring and winding gasket double seal structure.

2, packing seal structure, orbital plug valve spool in the valve switch process, both up and down to move and rotary movement, plus the particularity of the medium, in order to ensure the packing seal safe and reliable use of o-ring and packing combination seal

3, operating mechanism of the valve and self-locking, the cock valve operating mechanism (screw) adopts unique 1-shaped slot structure, move the cock of the axial line and 90 ° rotation apart, make the valve operation is flexible, lightweight.

4. special processing of key parts, the valve body cavity mechanical processing (grinding), after hard chromium plating treatment, the valve body cavity with corrosion resistance, erosion resistance, wear resistance, corrosion resistance. After mechanical processing of slide block (before pressing fluorine rubber), the slide block metal sealing surface is treated by hard chromium plating, so that it has the properties of corrosion resistance, erosion resistance, wear resistance and corrosion resistance. After the mechanical processing of the cock, after nickel plating treatment, the cock and the upper and lower shaft corrosion resistance, corrosion resistance. After rough machining, the valve stem is treated by tempering and tempering, and the surface hardness is no less than 900HV after finishing, which improves the anti-bite and anti-wear performance of the screw sleeve. The 1-shaped guide groove and the head of the guide key on the screw sleeve are processed and then quenched, no less than 45HRC, which improves the wear resistance and ensures that the guide key can slide freely in the guide groove.

5. Online adjustment and maintenance of packing. The track cock has a window for adjustment and maintenance of packing on both sides of the support.

6. Integral cock structure. The cock of track cock valve adopts integral casting structure. The cock is integrated with the upper and lower axes. When unidirectional compression is applied, ensure the upper and lower axes have enough rigidity, strength and bending resistance.

7, the valve cavity overpressure relief function, the pressure difference is caused by the change of environmental temperature. Double sealed valve in the closed state, the valve cavity of the medium with the increase of the ambient temperature volume expansion, pressure gradually increased, if not timely release the pressure difference, will have a serious impact on the operation of the valve, or even the expansion of the valve crack, to the safety of the system caused serious hidden trouble. Rail plug valves usually have three relief systems.

7.1 manual pressure relief system (for manual operation of the valve). Usually needle -type valves mounted on the valve body. When the valve is closed, open the pressure relief valve in the middle chamber, and release the medium in the valve body to the upstream of the pipeline or the atmosphere (check the sealing effect of the valve when releasing to the atmosphere).

7.2 differential pressure relief system (for manual and electric operation of valves). A piping system with a check valve. Isolation valve often open, when the valve is closed, through the one-way valve (check valve) in the body of the overpressure relief to the upstream valve and pipe connected. At the same time, the manual release valve can be opened to test the sealing effect of the valve. When the valve is opened, the manual release valve must be closed.

7.3 automatic pressure relief system (for electrically operated valves). When the valve is closed, the pressure relief valve will be opened automatically through the operating mechanism to connect the valve chamber with the upstream of the pipeline or the outside world.